Give your startup a competitive edge

MATRICS prioritizes manufacturing requests from startups, small businesses, research groups, student groups, and individuals. One-off prototypes and low volume production runs with a quick turnover rate at a competitive price can accelerate your progress and bring your business to greater heights.

By choosing MATRICS, you’re choosing quality. Our team will help you with design and manufacturing your project.

Services

-

Machining

CNC Mill Specs

3 Axis vertical mill

X Travel: 48” (1220mm)

Y Travel: 26” (660mm)

Z Travel: 24” (610mm)

Finishes: As machined, hand polished, electroplated -

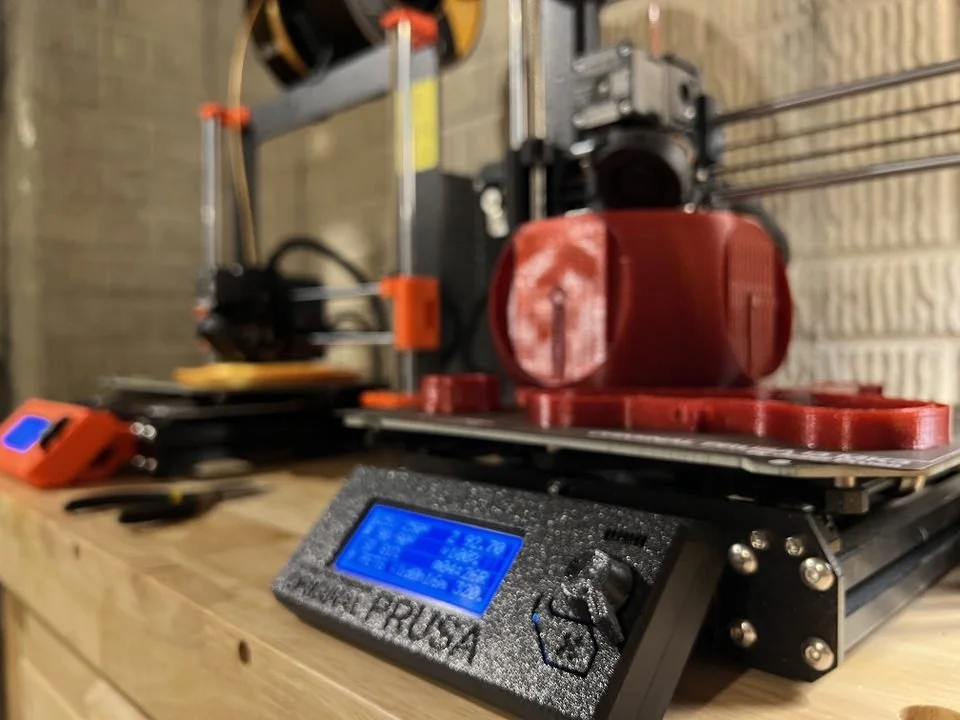

3D Printing

We have multiple Prusa I3 MK3S printers at our disposal and a wide range of filaments. Slicing and support removal is included with the service. Print settings, model editing, assembly, and post processing finishes can be requested as needed.

Refer to the quote sheet provided on the 3D Printing RFQ page for a comprehensive list of filaments provided, as well as an estimate on the cost.

Printer specs:

250x210x210mm build space

Nozzles sizes: 0.4mm, 0.25mm, 0.4mm (hardened steel)

Layer height: 0.1mm to 0.3mm

Supported filament: PLA, PETG, ABS, ASA, composites (woodfill, etc.)

-

Project Freelancing

This service exists to help bring new ideas to life. If a project requires multiple machined and/or printed parts or requires our team to design parts, opening a project file with us is the best option. The information you provide will give us the context we need to ensure the project is properly handled.

This option is best for smaller, independent creators looking to bring their idea to life or to strike up a low-stakes partnership with our machine shop.

Our team has a wide variety of skills we have employed in previous projects to great success. Please refer to the list below for a non-exhaustive list of skills we can employ.

-

Engineering Consulting

Our team is available for short-term design advice and long-term projects. While this option is not inherently different from our Project Freelancing service, the context is what matters. Our consulting service pertains moreso to technical projects, and the results of which can be less materially tangible depending on the scenario. For example, we can give guidance on how to machine parts or how to optimize processes while also prototyping and refining designs.

In short, Project Freelancing focuses on creating something new, while Engineering and Design Consulting emphasizes troubleshooting, R&D, advising, and interfacing with an already existing project.

Skills and Expertise

-

Engineering Design

Solidworks

Inventor

Fusion 360

Blender

Prusa Slicer

MATLAB

-

Technical Manufacturing

CNC Machining (3-axis)

3D Printing (FFF)

3D Printing (SLA)

Mold making (metal)

Mold making (silicone)

Carbon fiber (vacuum infusion)

Carbon fiber (prepreg)

Resin infusion

-

Artistic Manufacturing

Sanding/Polishing

Hand Painting

Spray Painting

Electroplating

Gilding

Sewing

Tailoring

Waterslide decals

Sublimation transfer paper decals

Card design and printing

Caligraphy

-

Electronics, Coding & Development

Hardware

Arduino

Breadboard prototyping

Motor Control

VR hardware

Software & Programming Languages

Unity development

VRChat development

Unreal development

Python

-

Regulation and Quality Assurance

ISO 13485/9001

IEC 14971

IEC 60601-1

IEC 62133

-

Digital Art

Programs

Blender

Krita

DaVinci Resolve

Streamlabs

Skills

2D digital art

3D character design

UV unwrapping & texturing